Manufacturing Solutions

Class-leading PCB production & inspection services

As high-performance technology continues to evolve, it’s becoming smarter, more compact, and lighter than ever before. These qualities are crucial for keeping your products at the cutting edge of innovation, allowing them to maintain a competitive edge in the market.

With precision and consistency as our focus, TechPoint supports clients with professional PCB production from initial concepts through to volume manufacturing. Our skilled team and state-of-the-art production facilities, paired with comprehensive technical and consultation services, mean we can bring your ideas to life with efficiency and confidence.

Our Solutions

PCB Production

With specialised expertise in PCB production, TechPoint is equipped to handle projects of all complexities, including high mix low to medium volume PCBA production and medium to high volume PCBA production. Whether you require a single-board solution or a fully integrated service, our advanced manufacturing centers offer the flexibility to adapt to your specific needs, ensuring a seamless process from start to finish.

We provide PCB design assistance to help optimize your designs for manufacturing, identifying potential issues that could impact performance or manufacturability. Our highly flexible lead times ensure your project stays on track, giving you the confidence that your vision will be realized without delay.

PCB Inspection

Thorough PCB inspection is crucial to ensure each product functions as intended, catching potential defects before they become costly issues. Our rigorous inspection process identifies and addresses production errors or design flaws early, leading to enhanced product reliability and performance.

By detecting issues such as soldering, circuitry, or component defects, we ensure compliance with industry standards while minimising rework and waste. Using advanced systems like Automated Optical Inspection (AOI), 3D X-rays, and high-resolution inspection microscopes, we guarantee precision and quality, extending the lifespan of your electronic products and reducing overall expenses.

Second Stage Processing

We offer a wide range of second-stage processing options to give your products the perfect finishing touch. By working closely with your hardware and mechanical teams, we ensure tailored solutions that meet your exact needs.

Our flexibility allows us to handle custom, small-batch, hand-built projects where automated equipment might not be suitable, making it possible to process through-hole components, press-fit components, custom LED assemblies, and non-standard SMT devices.

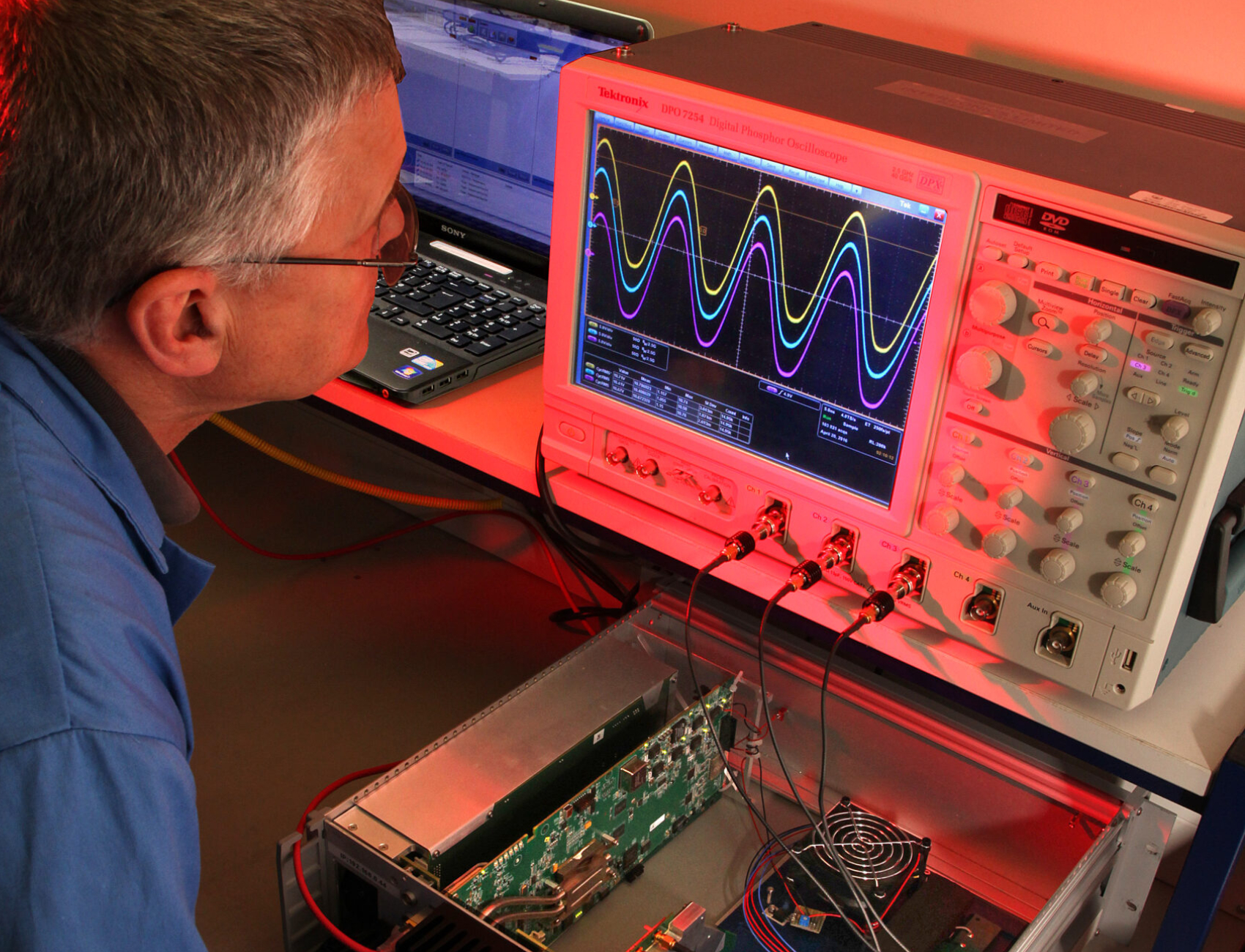

PCB Testing & Analysis

PCB testing and analysis is critical to ensuring that each board meets the highest standards of quality and reliability. At TechPoint, we use advanced testing methods to verify the integrity, functionality, and durability of every PCB we produce.

By combining precise analysis with cutting-edge equipment, we can detect flaws such as short circuits, open circuits, and other defects that might impact performance. Our thorough approach not only minimises the risk of failures but also ensures compliance with industry standards, providing you with the confidence that your products will perform as expected in real-world applications.

PCB Rework & Repairs

Our PCB rework and repair services utilise state-of-the-art equipment and advanced techniques to ensure precise and effective solutions. Our skilled technicians are equipped to handle everything from component removal and replacement to correcting complex issues like incorrect routing or suboptimal SMT footprints, which can impact performance and reliability.

Whether addressing minor defects or major repairs, our rework services can make all the difference in meeting tight deadlines and staying within budget. By thoroughly inspecting and refining your PCBs, we ensure your product meets the highest quality standards and is ready for market release with optimal functionality.